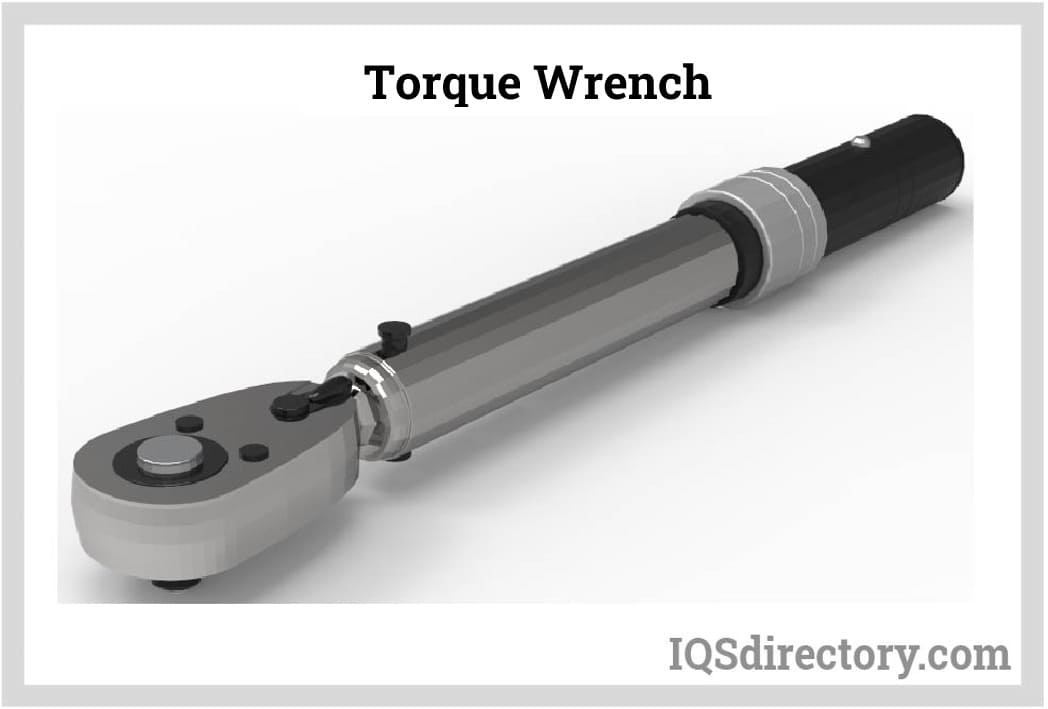

Torque wrenches have many uses in the automotive sector, including the assembly and disassembly of automobile engines, suspension parts, and lug nuts. Although torque wrenches are commonly used in the automotive industry, torque wrenches have far more extensive and diverse uses. Read More…

Custom Calibration specializes in on-site and laboratory calibration which will keep costly equipment downtime to a minimum and maximize your overall productivity. We have over 30 years of experience providing calibration services for mechanical, dimensional, scale, torque, humidity, and many more applications. Our company’s mission is to achieve total customer satisfaction by providing prompt, ...

ISO/IEC 17025:2017 & ANSI/NCSL Z540.3 Accredited Laboratory. Electronic, dimensional, physical and thermodynamic calibrations performed onsite and in our lab. Professional ASQ Certified Calibration Technicians. We support the manufacturing and service sectors including; aerospace, automotive, chemical, electronic equipment, energy, food, industrial, machinery, medical, metal, military, nuclear,...

Continental Testing specializes in calibration, repairs, and testing services for the aviation industry. We have dimensional, electrical, lighting, physical, chemistry, and avionics testing capabilities. We offer on-site testing in at least 30 states and provide expert services in aviation, railroad, plumbing, electronics, tool & die, and construction sectors.

At Micro Quality Calibration we are considered the first western commercial laboratory designed for precision measurements. Since 1978, our calibration laboratory & repair facility has done instrument calibration & equipment calibration. Calibration is done under strict controls. A2LA ISO/IEC 17025:2017 certified. We are successful because we provide the best service and are committed to...

In a world where precision is paramount, Constellation PowerLabs stands as a beacon of trust, offering calibration services that transcend mere measurements. We are a partner in progress, working hand-in-hand with organizations to enhance their operations through the lens of accuracy, quality, and reliability. When you choose Constellation PowerLabs, you choose a steadfast commitment to...

Sierra provides accurate calibration services for mass flow meters and controllers, insertion thermal flow meters, vortex, and ultrasonic flow meters. With more than 40 years of expertise in gas, air, or liquid flow calibration, you can count on our team to make sure your flow meter operates with efficiency and pinpoint accuracy. We believe in providing personalized and customized service, and...

At ENI Labs, we specialize in providing comprehensive calibration services tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted leader in calibration, renowned for our commitment to excellence, accuracy, and customer satisfaction. Our calibration services cover a wide range of equipment and...

More Torque Wrench Calibration Manufacturers

Torque wrenches are used for the disassembly and reassembly of heavy-duty machines. Torque wrenches need to be calibrated regularly to guarantee the security and integrity of the mechanical equipment one uses.

Why Wrenches Need to be Calibrated

Overtightening lug nuts can impair the internal or external threads of a lug nut or a stud, resulting in accidents similar to those caused by loose lug nuts. A torque wrench is used to ensure that lug nuts are neither too tight nor too loose. Engineers calculate the appropriate torque for lug nuts so that they neither apply too much gripping force to the wheel-axle system nor too little. However, a torque wrench's internal mechanism is mechanical and needs adjusting after a given amount of use. Torque wrench calibration is necessary because torque wrenches tend to lose their accuracy over time.

The aim of employing a torque wrench to ensure that no over- or under-tightening occurs. This purpose is completely defeated by utilizing an uncalibrated torque wrench because one may never know the tension at which it is tightening a fastener.

While a car's lug nuts are easily accessible and may be checked routinely, many other important fasteners, such as the engine's cylinder head bolts and connecting rod bolts, are harder to reach and may only get checked when an engine is overhauled. However, an engine may only be overhauled once every 10 to 20 years if proper maintenance is otherwise performed. As a result, these bolts must be tightened to the proper torque the first time.

Determining Torque Wrench Calibration Frequency

- Maximum inaccuracy must be allowed for a torque wrench application. For instance, a +/-4% error is acceptable in most applications. Still, a torque wrench with a +/-2% error may be needed for precision engineering research projects because anything less could skew the findings.

- The frequency of use also influences how often one should calibrate a torque wrench. For instance, a torque wrench used daily to tighten 100 bolts in an auto shop is likely to lose accuracy more quickly than one used occasionally for home improvement projects.

- Another element affecting the calibration frequency of a torque wrench is its typical torque wrench load. If a torque wrench has a maximum torque limit of 100 N.M (Newton Meter, a unit used to measure the tightening torque of precision tools), it is best to avoid using it to torque nuts and screws that need a torque of more than 80 N.M. This N.M. value is a common rule of thumb that technicians and workshops frequently follow. A torque wrench may need calibration sooner than the stipulated time, around the halfway point of its range, if it is used more frequently close to its maximum value.

- The operating environment might also impact the frequency of torque wrench calibration due to how temperature affects the metallurgy of the materials used to create the torque wrench's parts. The accuracy of a torque wrench varies with the seasons because metals expand in heat and contract at cooler temperatures. However, the accuracy loss is small for most practical applications. For applications requiring precise engineering, however, this issue is more critical.

- Storage circumstances might also impact the accuracy of torque wrenches. For instance, there is a need to crank down the micrometer click-type torque wrench to its lowest setting to reduce spring tension and maintain precision while storing.

Torque Wrench Calibration Process

Regardless of how often the process may be needed, torque wrench calibration is important to ensure that both the torque wrench, and everything it works with, functions properly. There are professional facilities that perform this responsibility. Depending on the frequency of calibration, it may make financial sense to perform this procedure on your own. Either way, the calibration process remains the same.

- Rotate the torque wrench to the 20% position. Record the torque amount at which the torque wrench clicks using a torque-measuring instrument.

- Determine the error rate. For instance, if one sets a measuring instrument to 20 N.M. and the wrench reads 24 N.M., there is a 4 N.M. (20%) inaccuracy.

- Repeat steps 1 and 2 for torque levels of 60% and 100%, respectively.

- Unlock the locking nut on the click-type torque wrench and modify the spring tension system by the manufacturer's instructions.

- After completing these steps, shut off the torque wrench to see if the error has decreased to the desired range.

- It is a success if the error has been decreased to an acceptable level (+/-4% for mechanical click type torque wrenches above the 10 N.M limit and +/-6% for torque wrenches less than the 10 N.M limit) and alternatively, there is a need to repeat the above procedures if the error is still outside of acceptable bounds. If the torque wrench is out of an acceptable level, repeat the process until it finally is brought to the proper range.

Choosing the Proper Torque Wrench Calibration Supplier

To make sure you have the most productive outcome when purchasing Torque Wrench Calibration from a Torque Wrench Calibration Company, it is important to compare at least 6 Companies using our Torque Wrench Calibration directory. Each Torque Wrench Calibration Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Torque Wrench Calibration company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Torque Wrench Calibration companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services