Force calibration is the process of determining the accuracy of a force measurement device or instrument,Examples of equipment requiring force calibration include scales, load cells, force gauges, and other force measurement devices. Force calibration is critical for equipment because it ensures reliability, accuracy, and traceability to recognized standards. Inaccurate force measurements can lead to product defects, safety issues, and increased costs. Read More…

Custom Calibration specializes in on-site and laboratory calibration which will keep costly equipment downtime to a minimum and maximize your overall productivity. We have over 30 years of experience providing calibration services for mechanical, dimensional, scale, torque, humidity, and many more applications. Our company’s mission is to achieve total customer satisfaction by providing prompt, ...

ISO/IEC 17025:2017 & ANSI/NCSL Z540.3 Accredited Laboratory. Electronic, dimensional, physical and thermodynamic calibrations performed onsite and in our lab. Professional ASQ Certified Calibration Technicians. We support the manufacturing and service sectors including; aerospace, automotive, chemical, electronic equipment, energy, food, industrial, machinery, medical, metal, military, nuclear,...

For over 40 years, Strainsert Company has been an industry leader in manufacturing calibration services. Our goal is to provide calibrating services that are thorough and accurate, and we have experience serving a variety of applications.

SensoScientific is a leading manufacturer of practical and innovative wireless systems that meet the needs of the ever-changing healthcare industry. We design, engineer, and manufacture our own transmitters and firmware. This helps ensure seamless system functionality with zero dependencies on third-party manufacturers. Our products include temperature monitoring systems, temperature control...

Sierra provides accurate calibration services for mass flow meters and controllers, insertion thermal flow meters, vortex, and ultrasonic flow meters. With more than 40 years of expertise in gas, air, or liquid flow calibration, you can count on our team to make sure your flow meter operates with efficiency and pinpoint accuracy. We believe in providing personalized and customized service, and...

The origins of force calibration can be traced back to ancient times when measuring weights and forces was necessary for trade, commerce, and engineering. Today, force calibration is essential in various industries that rely on precise force measurements.

Process of Force Calibration

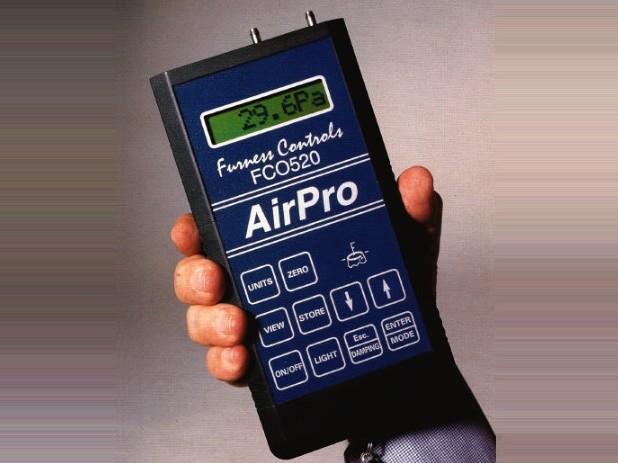

There are different methods of force calibration, such as deadweight testers, force proving instruments, or calibration machines. Proper equipment selection is essential for accurate and precise force calibration. The calibration equipment must be compatible with the device under test and meet or exceed the required accuracy and precision specifications. Perhaps ironically, regular maintenance and calibration of calibration equipment are necessary to ensure accuracy and traceability. The calibration process typically involves comparing the device under test to known standards or reference weights or forces and adjusting the device’s internal settings or output signal to match the reference values. The creation of a calibration certificate provides information on the device’s accuracy, traceability, and calibration date.

Limitations of Force Calibration

Factors that can affect the accuracy of force measurements include temperature, humidity, vibrations, and other environmental conditions. Calibration equipment and reference standards must be regularly maintained and calibrated to ensure accuracy and traceability. Challenges in force calibration include access to reference standards, calibration frequency, and training and expertise of calibration personnel.

Benefits of Force Calibration

The benefits of force calibration include increased reliability and efficiency, reduced downtime and maintenance costs, and improved product quality and safety. Accurate force measurements also ensure compliance with industry and regulatory standards and provide confidence in measurement results. Traceability to recognized standards is essential in the global marketplace, where products and services must meet stringent quality and safety requirements.

Applications of Force Calibration

Force calibration is crucial in industries that rely on precise force measurements, such as manufacturing, aerospace, automotive, and medical equipment. Force calibration is also important in research and development, where accurate force measurements are necessary to study the properties and behavior of materials and structures.Specific applications of force calibration include tension and compression testing, torque testing, hardness testing, and more. We look at these various types of tests and the industries benefiting from force calibration in greater detail below.

Types of Force Calibration Testing

Tension and Compression Testing: Force calibration is essential for tension and compression testing, where a sample is subjected to a force to measure its strength, durability, or other properties. Examples include testing the strength of materials like steel, plastic, or rubber, or evaluating the performance of mechanical components like springs or bearings. Accurate force measurements are crucial in such applications to ensure safety and compliance with industry standards.

Torque Testing: Torque calibration involves measuring the force required to rotate a shaft or screw. This type of calibration is important in various industries where accurate torque measurements are necessary for the assembly, maintenance, or repair of machines and equipment. Examples include testing the torque of bolts, nuts, or screws in automotive engines or aircraft structures.

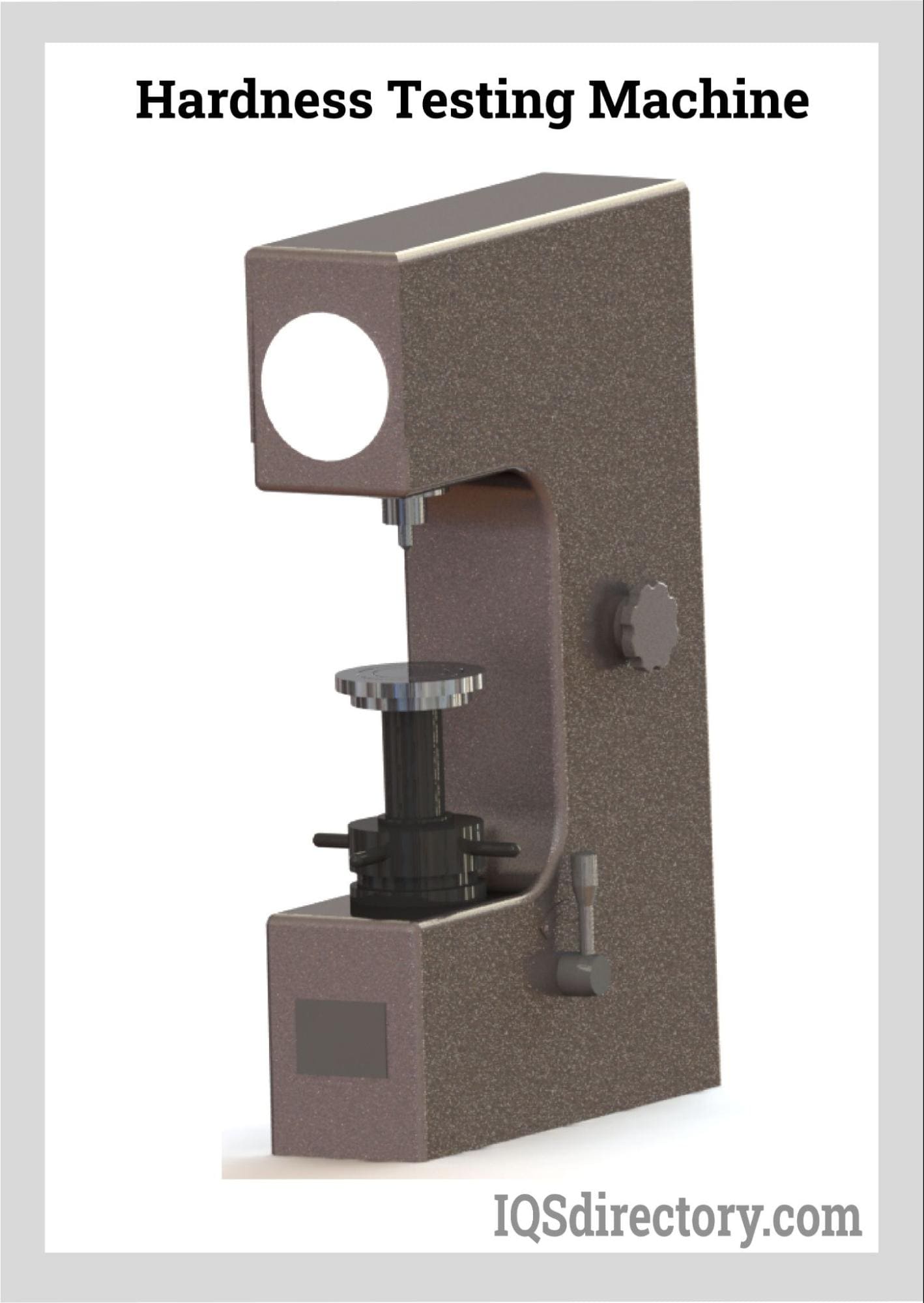

Hardness Testing: Force calibration is also important in hardness testing, where a sample’s resistance to indentation or deformation is measured to determine its hardness. Examples include testing the hardness of metals, plastics, or composites, or evaluating the wear resistance of materials. Accurate force measurements are necessary in such applications to ensure reproducibility and reliability of measurement results.

Industries Requiring Force Calibration

As previously mentioned, force calibration is used in many different industries, and different types of calibration are used depending on the specific application. Here are some examples:

Manufacturing Industry: Force calibration is used extensively in the manufacturing industry for quality control and product testing. For example, compression testing is used to evaluate the strength and durability of materials such as plastics, rubber, and metals. Torque calibration is also essential in the manufacturing of machinery, engines, and other mechanical components. In addition, force calibration is used to ensure accuracy in the assembly of products, such as electronic devices and aerospace components.

Automotive Industry: Force calibration is used in the automotive industry for a wide range of applications, from testing the strength of car parts to measuring the torque of engine bolts. Tension and compression testing is used to evaluate the strength of various automotive components, including suspension systems, steering mechanisms, and chassis components. Torque calibration is critical for the accurate assembly of engines and transmissions, and for ensuring that fasteners are tightened to the correct specifications.

Aerospace Industry: Force calibration is used extensively in the aerospace industry to ensure safety and reliability in critical components such as engines, landing gear, and flight control systems. Torque calibration is used to ensure that fasteners are tightened to the correct specifications and that components are properly assembled. Tension and compression testing is used to evaluate the strength and durability of materials used in aerospace applications, such as carbon fiber composites.

Medical Industry: Force calibration is essential in medical testing and research, where precise force measurements are necessary to evaluate the properties and behavior of biological tissues, fluids, and structures. Force calibration is essential for ensuring the safety and effectiveness of medical devices, as well as for conducting research into the properties of biological tissues and fluids. Examples include testing the strength of bones, cartilage, or muscles, or measuring the pressure or flow rate of blood vessels or respiratory systems. Accurate force measurements are critical in such applications to ensure safety and effectiveness of medical treatments and devices. Force calibration is also used for a variety of applications, including testing the strength of orthopedic implants, measuring the force required for injections, and evaluating the performance of prosthetic devices.

Research and Development: Force calibration is also used extensively in research and development across a wide range of industries, including materials science, mechanical engineering, and biotechnology. Examples include testing the mechanical properties of materials, studying the behavior of structures under load, or evaluating the performance of sensors and actuators. Accurate force measurements are necessary in such applications to ensure reproducibility and reliability of research results.

Choosing the Right Force Calibration Service

To ensure the most positive outcome when purchasing force calibration from a force calibration company, it is important to use our directory to compare several force calibration services. Each force calibration service has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or request a quote. Review each force calibration business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple force calibration companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services