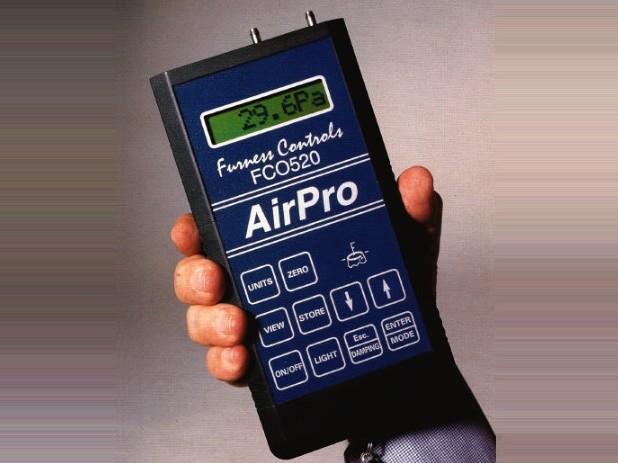

To use them, operators attach the calibrator directly to the sensing instrument, along with the substance it is meant to measure. For example, to make sure a food thermometer is working correctly, they can drop it into a cup of ice water, along with your calibration device. While the temperature testing device is emerged, operators can see what temperature it displays in comparison to the temperature the calibrator displays. Read More…

Custom Calibration specializes in on-site and laboratory calibration which will keep costly equipment downtime to a minimum and maximize your overall productivity. We have over 30 years of experience providing calibration services for mechanical, dimensional, scale, torque, humidity, and many more applications. Our company’s mission is to achieve total customer satisfaction by providing prompt, ...

ISO/IEC 17025:2017 & ANSI/NCSL Z540.3 Accredited Laboratory. Electronic, dimensional, physical and thermodynamic calibrations performed onsite and in our lab. Professional ASQ Certified Calibration Technicians. We support the manufacturing and service sectors including; aerospace, automotive, chemical, electronic equipment, energy, food, industrial, machinery, medical, metal, military, nuclear,...

Continental Testing specializes in calibration, repairs, and testing services for the aviation industry. We have dimensional, electrical, lighting, physical, chemistry, and avionics testing capabilities. We offer on-site testing in at least 30 states and provide expert services in aviation, railroad, plumbing, electronics, tool & die, and construction sectors.

At Cross Precision Measurement, we are dedicated to providing industry-leading products, services, and capabilities to meet the diverse needs of our clients. Our expertise lies in delivering precise measurement solutions that enhance operational efficiency and ensure the highest standards of quality. We pride ourselves on our state-of-the-art equipment and innovative approaches, making us a...

In a world where precision is paramount, Constellation PowerLabs stands as a beacon of trust, offering calibration services that transcend mere measurements. We are a partner in progress, working hand-in-hand with organizations to enhance their operations through the lens of accuracy, quality, and reliability. When you choose Constellation PowerLabs, you choose a steadfast commitment to...

Sierra provides accurate calibration services for mass flow meters and controllers, insertion thermal flow meters, vortex, and ultrasonic flow meters. With more than 40 years of expertise in gas, air, or liquid flow calibration, you can count on our team to make sure your flow meter operates with efficiency and pinpoint accuracy. We believe in providing personalized and customized service, and...

Kent Machine, Inc., founded in 1980, is devoted to excellence in calibration and repair of electronic and physical/dimensional test equipment. We offer calibration to accommodate the customer with large quantities of equipment to calibrate, eliminating downtime or expense of sending the equipment out, and for equipment too large to move. Visit our website today to learn more about our calibration ...

More Temperature Calibration Manufacturers

The value that the calibrator displays is the correct one. If the temperature is off at all, they can then adjust the sensing device until it matches the value displayed on the calibrator. Once the task is complete, a technician will detail the test and certify the accuracy of the sensing device. Temperature calibration is important for a wide variety of reasons. First, it ensures the safety of many foods. Food that is too cold or, more often, too hot, can be dangerous to consume. Food above a certain temperature is susceptible to bacterial growth. Scalding hot food can also burn you. Temperature calibration also ensures the safety and high quality of other substances, such as fuel or lab chemicals.

Temperature calibration is essential in industries such as: food and beverage, meteorology, automotive, aerospace, industrial cleaning, laboratory, research, chemical processing, healthcare and manufacturing. People in these industries use temperature calibration at various points in the life of a system or instrument. For example, system operators typically calibrate their temperature sensing devices when they first install it. Many system operators also check calibrate their devices from time to time to make sure that they have not become inaccurate. Inaccurate readings can occur as a result of jarring events like vibration and shock. In addition, they use temperature calibration if and when their devices offer up an unlikely or problematic reading.

Temperature calibration is generally fast and easy. It has virtually no downsides. The only questions you will need to answer are what type of temperature calibration method is best for you, and how often you should calibrate your system or instruments. To learn more about the options available to you, check out the services and products offered by those temperature calibration providers we’ve listed on this page.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services