Sierra Instruments

Sierra InstrumentsRequest A Quote

Monterey, CA | 831-373-0200https://www.sierrainstruments.com/calrepair/calrepair.html

Founded in 1971, Sierra Instruments quickly earned its role as an industry leader providing cost efficient high-performance fluid flow measurement and control instrumentation. Like our product line, this role and reputation for excellence has only improved over time with more than 150 locations in over 50 countries to provide a robust network of customer service and support. We understand the importance of customer service and strive to meet each and every one of our customers’ goals to ensure satisfaction.

Sierra serves customers not only across the globe, but also throughout the industrial sector. Standard and customized flow indicators , controls and measurement instrumentation ensure that the company offers the most cost-effective and overall efficient piece of equipment for any process. Recipients of all Sierra ultrasonic, vortex, peak and other flow products, whether standard or customized, also receive customized support and service. The Sierra team values our unique relationship with every client, going well beyond the point of purchase to ensure optimum operation and understanding.

Our website furthers the dedication to customer service, offering a live help feature for immediate feedback, and communication with knowledgeable agents. Our constant search for solutions is inherent in Sierra, not only in response to individual customer challenges, but to global issues as well. As an increasing number of clean energy and energy efficiency applications emerge, we look forward to developing ever better technology to manage and maintain process flow. With 40 years of industry leadership, there is no doubt that Sierra Instruments will meet these challenges. No matter the industry, no matter the location, Sierra’s passion for flow ensures a steady stream of innovation.

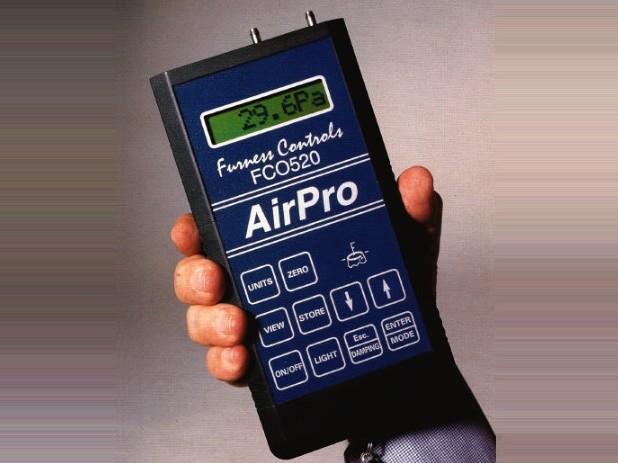

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services