To use them, operators attach the calibrator directly to the sensing instrument, along with the substance it is meant to measure. For example, to make sure a food thermometer is working correctly, they can drop it into a cup of ice water, along with your calibration device. While the temperature testing device is emerged, operators can see what temperature it displays in comparison to the temperature the calibrator displays. Read More…

Custom Calibration specializes in on-site and laboratory calibration which will keep costly equipment downtime to a minimum and maximize your overall productivity. We have over 30 years of experience providing calibration services for mechanical, dimensional, scale, torque, humidity, and many more applications. Our company’s mission is to achieve total customer satisfaction by providing prompt, ...

ISO/IEC 17025:2017 & ANSI/NCSL Z540.3 Accredited Laboratory. Electronic, dimensional, physical and thermodynamic calibrations performed onsite and in our lab. Professional ASQ Certified Calibration Technicians. We support the manufacturing and service sectors including; aerospace, automotive, chemical, electronic equipment, energy, food, industrial, machinery, medical, metal, military, nuclear,...

At MSI-Viking Gage, LLC, we are dedicated to providing industry-leading calibration services that are both comprehensive and adaptable to meet the diverse needs of our clients. With extensive ISO 17025 Accredited and ISO 9001 Certified calibration capabilities, we ensure that every measurement and calibration we perform adheres to the highest standards of accuracy and reliability. Our services...

Fox Valley Metrology provides calibration and repair services for various types of measuring instruments, including dimensional, electrical, and mechanical equipment. We have been in the industry for almost 30 years, serving clients across various industries, including aerospace, automotive, medical, and manufacturing. We aim to provide quality and accurate calibration services that meet or...

Standard Calibrations offers quality calibrating services, gage calibration services and more. We offer calibrating services that will handle your needs from the smallest meter to complete propulsion control systems. We have a calibration laboratory and pressure calibration devices to serve you.

At Advanced Measurement Streamlined Precision, we dedicate ourselves to delivering calibration services that ensure accuracy, reliability, and consistency across a wide range of instruments and equipment. We recognize that precise measurement is the backbone of any technical operation, and we approach each project with the goal of providing confidence in every reading.

Sierra provides accurate calibration services for mass flow meters and controllers, insertion thermal flow meters, vortex, and ultrasonic flow meters. With more than 40 years of expertise in gas, air, or liquid flow calibration, you can count on our team to make sure your flow meter operates with efficiency and pinpoint accuracy. We believe in providing personalized and customized service, and...

More Temperature Calibration Manufacturers

Comprehensive Guide to Temperature Calibration: Importance, Applications, and Best Practices

Reliable temperature calibration is a cornerstone of quality assurance and operational safety in a wide range of industries. Whether you are overseeing food safety, laboratory research, industrial manufacturing, or aerospace engineering, ensuring accurate temperature measurement is critical to both compliance and performance. But what exactly is temperature calibration, and why is it so vital across so many sectors?

What is Temperature Calibration?

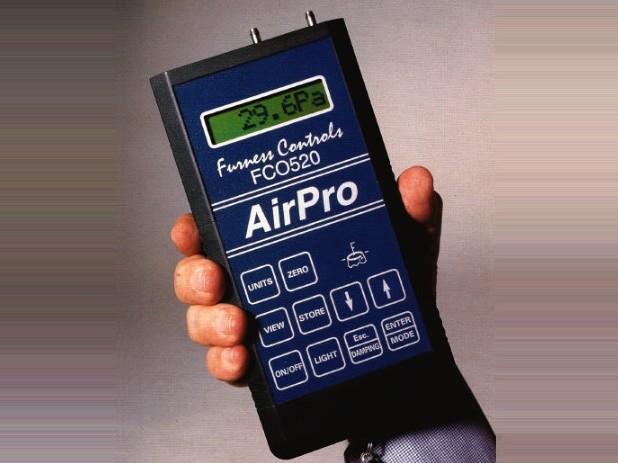

Temperature calibration is the process of verifying and adjusting the accuracy of a temperature-measuring device, such as a sensor, thermometer, or temperature transmitter, by comparing its measurements to a known and traceable standard—usually a high-precision temperature calibrator. Through this process, technicians can ensure that the readings provided by the device are both precise and reliable, minimizing the risk of error in sensitive applications.

How Does Temperature Calibration Work?

The calibration process begins by using a reference instrument (the calibrator), which displays the true temperature value. The device under test is exposed to the same temperature conditions as the calibrator. If there is a deviation between the device's reading and the calibrator’s value, adjustments can be made to the sensing device until both readings match. After the calibration is complete, a technician documents the process and certifies the device’s accuracy, often providing a traceable calibration certificate to satisfy regulatory, industry, or quality management standards.

Why is Temperature Calibration Important?

Accurate temperature measurement is essential for a broad range of reasons:

- Food Safety and Quality: In the food and beverage industry, incorrect temperature readings can result in unsafe or spoiled products. Food stored or cooked at improper temperatures is at risk for bacterial growth, while excessively hot food can cause burns or degrade product quality.

- Laboratory and Research Accuracy: Scientific laboratories, testing facilities, and research environments depend on precise temperature control to ensure the validity and repeatability of experiments and analytical results.

- Industrial and Manufacturing Processes: Temperature calibration is vital in process industries such as chemical processing, pharmaceuticals, and manufacturing, where product quality and system safety hinge on correct temperature regulation.

- Healthcare and Medical Devices: Accurate temperature monitoring in healthcare settings is critical for sterilization, storage of medications, and patient care applications.

- Aerospace and Automotive: In aerospace and automotive engineering, reliable temperature sensors ensure system performance and safety during production, testing, and operation.

Without routine calibration, temperature sensing devices can drift due to normal wear, exposure to harsh environments, or mechanical shock and vibration. This can lead to costly errors, safety hazards, regulatory violations, or compromised product integrity.

Industries That Rely on Temperature Calibration

Many sectors depend on regular temperature calibration to maintain compliance and ensure operational excellence. Common industries include:

- Food and Beverage Processing

- Clinical Laboratories and Healthcare Facilities

- Pharmaceutical Manufacturing

- Chemical and Petrochemical Plants

- Automotive and Aerospace Engineering

- Environmental Monitoring and Meteorology

- Industrial Cleaning and Sterilization

- Research and Academic Laboratories

- Electronics and Semiconductor Manufacturing

- Power Generation and Utilities

- Calibration Laboratories

When Should Temperature Calibration Be Performed?

Deciding how often to calibrate your temperature instruments depends on several factors:

- Initial Installation: Devices should be calibrated upon installation to ensure baseline accuracy.

- Scheduled Maintenance: Most industries follow a regular calibration schedule based on manufacturer recommendations, regulatory requirements, or best practices—often annually, semi-annually, or quarterly.

- Post-Event Calibration: Temperature sensors and devices should be recalibrated after exposure to physical shocks, extreme temperatures, electrical surges, or any event that might affect accuracy.

- Unusual or Problematic Readings: If your system reports unexpected or inconsistent temperature values, immediate calibration is recommended to rule out sensor drift or malfunction.

For help determining the right calibration interval for your application, consult with an accredited calibration laboratory or temperature calibration specialist.

Methods of Temperature Calibration

There are several methods used to calibrate temperature-sensing devices, each suited to different types of equipment and accuracy requirements:

- Dry Block Calibrators: These portable devices provide stable temperature environments for calibrating thermocouples, RTDs (resistance temperature detectors), and other sensors. They are widely used for field and laboratory calibration.

- Liquid Bath Calibrators: By immersing sensors in a precisely controlled liquid bath, this method allows for multi-point calibration and is ideal for high-accuracy applications.

- Infrared Calibration: Non-contact infrared thermometers and thermal imaging devices require specialized blackbody sources for calibration.

- Comparison with Reference Thermometers: Here, the device under test is compared against a certified reference thermometer under identical conditions.

- Fixed-Point Calibration: This method uses substances with well-defined freezing or melting points (such as pure water, gallium, or tin) to calibrate high-accuracy sensors in research and standards laboratories.

Want to learn which calibration method is right for your instruments? Ask: What is the best temperature calibration method for my application? or How do I choose between dry block and liquid bath calibration?

Types of Temperature Sensing Devices That Require Calibration

Many different temperature measurement devices benefit from regular calibration, including:

- Thermocouples (Types K, J, T, E, N, R, S, and B)

- Resistance Temperature Detectors (RTDs)

- Thermistors

- Glass Thermometers

- Infrared Thermometers

- Temperature Transmitters

- Thermal Cameras and Infrared Imaging Devices

- Data Loggers and Process Controllers

Are you unsure if your device needs calibration? Search: Does my temperature sensor require calibration? or How to calibrate a thermocouple vs. an RTD?

Key Benefits of Regular Temperature Calibration

Routine calibration offers numerous advantages that directly impact quality, safety, and operational efficiency:

- Compliance with Industry Standards: Many regulatory agencies and quality management systems (such as ISO 9001, ISO/IEC 17025, FDA, and HACCP) require routine calibration of temperature measurement devices.

- Quality Assurance: Accurate temperature readings are crucial for process control, product quality, and end-user safety.

- Risk Reduction: Prevent costly errors, product recalls, or equipment failures due to inaccurate temperature measurements.

- Cost Savings: Minimize downtime, waste, and rework by ensuring your devices perform within specified tolerances.

- Traceability and Audit Readiness: Calibration records provide a documented trail for audits, inspections, and root cause analysis.

- Extended Equipment Lifespan: Well-maintained sensors and instruments last longer, reducing replacement costs.

How to Select a Temperature Calibration Service Provider

Choosing the right calibration partner is essential for reliable results and audit compliance. Consider the following factors when evaluating temperature calibration service providers:

- Accreditation: Look for ISO/IEC 17025-accredited laboratories, which demonstrate technical competence and adherence to international standards.

- Experience and Expertise: Select providers with a proven track record in your specific industry and with your types of instruments.

- Traceable Calibration Standards: Ensure the provider uses reference standards traceable to NIST or another national metrology institute.

- Comprehensive Service Offering: Does the provider offer on-site, in-lab, and field calibration options?

- Turnaround Time and Support: Fast, responsive service and clear documentation are vital for minimizing downtime and meeting regulatory deadlines.

- Calibration Documentation: Detailed calibration certificates with as-found/as-left data, uncertainty values, and traceability information are best practices.

Looking for temperature calibration services near you? Search: Find accredited temperature calibration laboratories in [your location] or Best temperature calibration providers for [your industry].

Common Applications and Use Cases for Temperature Calibration

Temperature calibration underpins safe and efficient operation in numerous real-world scenarios, including:

- Cold Chain Monitoring: Ensuring pharmaceuticals, vaccines, and perishable foods are kept within safe temperature ranges during storage and transportation.

- Process Control in Manufacturing: Maintaining precise thermal conditions for chemical reactions, curing, or baking processes.

- Environmental Monitoring: Accurate field temperature measurement for climate research, weather stations, or environmental compliance.

- Medical Sterilization: Verifying autoclave and sterilizer performance in hospitals and clinics.

- Cleanroom and Laboratory Monitoring: Ensuring consistent environmental conditions in sensitive research and semiconductor fabrication.

- Automotive and Aerospace Testing: Validating component and system performance under extreme thermal conditions.

- Energy and Utilities: Monitoring temperature in boilers, turbines, and critical infrastructure.

Wondering how temperature calibration improves your process? Ask: How does temperature calibration support regulatory compliance and quality assurance in my industry?

Frequently Asked Questions (FAQs) About Temperature Calibration

How often should I calibrate my temperature sensors?

Most manufacturers recommend annual calibration, but high-precision or mission-critical applications may require more frequent calibration. Environmental factors, frequency of use, and regulatory guidelines should all inform your calibration schedule.

What are the consequences of not calibrating my temperature instruments?

Failure to calibrate can result in inaccurate readings, product quality issues, regulatory violations, potential safety hazards, and increased costs due to waste or rework.

Can I perform temperature calibration in-house?

Many organizations with the required expertise and equipment can carry out basic calibrations in-house. However, accredited third-party laboratories offer the highest level of traceability, precision, and documentation, often required for compliance and audits.

What is a calibration certificate, and why is it important?

A calibration certificate documents the results of a calibration process, including as-found and as-left data, measurement uncertainty, reference standards used, and traceability information. It is essential for compliance, audits, and quality management systems.

How do I know if my calibration provider is accredited?

Accredited laboratories are listed with national accreditation bodies (such as A2LA, ANAB, or UKAS) and should provide accreditation certificates and scope of services upon request. Always verify a provider’s qualifications before contracting services.

Temperature Calibration Resources and Next Steps

If you are ready to improve your process control, regulatory compliance, and product quality with expert temperature calibration, explore the following resources:

Still have questions about temperature calibration, or need help selecting the right solution for your application? Contact a calibration specialist or request a quote to get expert guidance tailored to your needs.

For ongoing updates, compliance tips, and industry news, bookmark this page or subscribe to our newsletter for the latest on temperature calibration, measurement technology, and quality management.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services