Instrument calibration is a critical process that ensures the accuracy and reliability of measurement instruments. It involves comparing the reading of an instrument to a known reference or standard, adjusting the instrument as necessary, and then documenting the results of the comparison. The primary purpose of instrument calibration is to ensure that the measurements taken by the instrument are accurate and reliable. Read More…

Custom Calibration specializes in on-site and laboratory calibration which will keep costly equipment downtime to a minimum and maximize your overall productivity. We have over 30 years of experience providing calibration services for mechanical, dimensional, scale, torque, humidity, and many more applications. Our company’s mission is to achieve total customer satisfaction by providing prompt, ...

ISO/IEC 17025:2017 & ANSI/NCSL Z540.3 Accredited Laboratory. Electronic, dimensional, physical and thermodynamic calibrations performed onsite and in our lab. Professional ASQ Certified Calibration Technicians. We support the manufacturing and service sectors including; aerospace, automotive, chemical, electronic equipment, energy, food, industrial, machinery, medical, metal, military, nuclear,...

Continental Testing specializes in calibration, repairs, and testing services for the aviation industry. We have dimensional, electrical, lighting, physical, chemistry, and avionics testing capabilities. We offer on-site testing in at least 30 states and provide expert services in aviation, railroad, plumbing, electronics, tool & die, and construction sectors.

At Micro Quality Calibration we are considered the first western commercial laboratory designed for precision measurements. Since 1978, our calibration laboratory & repair facility has done instrument calibration & equipment calibration. Calibration is done under strict controls. A2LA ISO/IEC 17025:2017 certified. We are successful because we provide the best service and are committed to...

In a world where precision is paramount, Constellation PowerLabs stands as a beacon of trust, offering calibration services that transcend mere measurements. We are a partner in progress, working hand-in-hand with organizations to enhance their operations through the lens of accuracy, quality, and reliability. When you choose Constellation PowerLabs, you choose a steadfast commitment to...

Sierra provides accurate calibration services for mass flow meters and controllers, insertion thermal flow meters, vortex, and ultrasonic flow meters. With more than 40 years of expertise in gas, air, or liquid flow calibration, you can count on our team to make sure your flow meter operates with efficiency and pinpoint accuracy. We believe in providing personalized and customized service, and...

At ENI Labs, we specialize in providing comprehensive calibration services tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted leader in calibration, renowned for our commitment to excellence, accuracy, and customer satisfaction. Our calibration services cover a wide range of equipment and...

More Instrument Calibration Manufacturers

Why Instruments Need Calibration

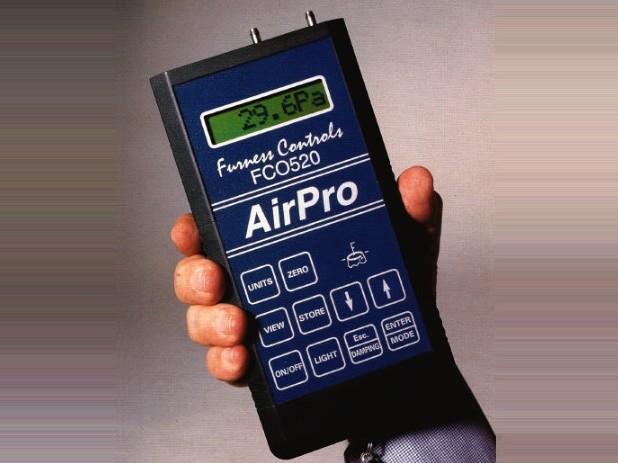

A wide range of instruments require calibration, including temperature sensors, pressure gauges, flow meters, and analytical instruments such as spectrophotometers and chromatographs. The need for calibration arises from several factors, including wear and tear of the instrument, changes in environmental conditions, and drift of electronic components over time.

Process of Instrument Calibration

The general process of instrument calibration involves several steps that ensure the accuracy and reliability of the instrument:

Select an Appropriate Reference Standard

The first step in instrument calibration is to select a reference standard that is traceable to a national or international standard. This ensures that the reference standard is accurate and reliable, and the calibration results can be traced back to a known standard.

Establish a Calibration Interval

The calibration interval is the frequency at which the instrument should be calibrated. This interval is typically determined based on the instrument's usage, the environment in which it is used, and the manufacturer's recommendations.

Perform the Calibration

The calibration process involves comparing the instrument's readings to the reference standard and adjusting the instrument as necessary. This may involve adjusting the instrument's settings or making mechanical adjustments to the instrument.

Document the Results

The results of the calibration should be documented to provide a record of the instrument's accuracy and reliability. The documentation should include the calibration date, the reference standard used, the calibration procedure, and the calibration results.

Analyze the Results

After the calibration is complete, the results should be analyzed to determine if the instrument is within acceptable limits of accuracy and reliability. If the instrument is not within acceptable limits, further adjustments or repairs may be necessary.

Update the Calibration Record

The calibration record should be updated with the results of the calibration and any adjustments or repairs that were made. This ensures that a complete and accurate history of the instrument's calibration is maintained.

The specific steps involved in instrument calibration may vary depending on the type of instrument and the industry in which it is used. For example, the calibration process for a medical device may involve additional steps to ensure compliance with regulatory requirements that are not required for instruments used in other industries. Additionally, the process of instrument calibration can vary depending on the specific application. For example, instruments used in critical applications, such as aviation, may require more stringent calibration procedures compared to instruments used in less critical applications.

Considerations Regarding Instrument Calibration

One consideration regarding instrument calibration is that it can be time-consuming and costly. Additionally, the accuracy of the reference standard used for calibration can affect the overall accuracy of the instrument. Therefore, it is important to ensure that the reference standard used for calibration is itself accurate and reliable.

Benefits of Instrument Calibration

The benefits of instrument calibration include improved accuracy and reliability of measurements, increased product quality and consistency, reduced downtime, and increased customer satisfaction. Additionally, calibration can help to identify potential issues with the instrument before they become major problems, potentially saving time and money in the long run.

Applications of Instrument Calibration

Instrument calibration has a wide range of applications across various industries, including:

Pharmaceutical Manufacturing

Pharmaceutical manufacturing facilities require highly precise measurements to ensure the safety and efficacy of their products. Examples of instruments that may require calibration in this industry include analytical instruments such as spectrophotometers, chromatographs, and pH meters, as well as temperature and humidity sensors.

Food and Beverage Production

The food and beverage industry also requires precise measurements to ensure the quality and safety of their products. Examples of instruments that may require calibration in this industry include temperature sensors, pH meters, and refractometers.

Environmental Monitoring

Environmental monitoring involves the measurement of various parameters such as air quality, water quality, and soil quality. Examples of instruments that may require calibration in this industry include gas sensors, particulate monitors, and pH meters.

Automotive Manufacturing

Automotive manufacturing facilities use a wide range of instruments to measure parameters such as temperature, pressure, and flow rate. Examples of instruments that may require calibration in this industry include pressure gauges, thermocouples, and flow meters.

Aerospace and Defense

Aerospace and defense industries require highly precise and reliable measurements for critical applications. Examples of instruments that may require calibration in this industry include accelerometers, pressure sensors, and temperature sensors.

Medical Equipment Manufacturing

Medical equipment must meet stringent regulatory requirements and quality standards. Examples of instruments that may require calibration in this industry include patient monitors, infusion pumps, and anesthesia machines.

Oil and Gas Production

Oil and gas production facilities require precise measurements to ensure the safety and efficiency of their operations. Examples of instruments that may require calibration in this industry include flow meters, pressure gauges, and temperature sensors.

Aviation

Aviation is another industry that requires precise and reliable measurements for critical applications. Examples of instruments that may require calibration in this industry include altimeters, airspeed indicators, and gyroscopes.

In-House vs. Outsourced Instrument Calibration

Instrument calibration can be performed either in-house or outsourced to a third-party calibration service. In-house calibration can be more cost-effective and convenient, as it allows for greater control over the calibration process. However, outsourcing calibration can be beneficial when specialized equipment or expertise is required, or when there is a need to comply with industry regulations or standards. Additionally, outsourcing calibration services can be more cost-effective than performing it in-house in certain cases as it eliminates the need to purchase and maintain calibration equipment, hire and train calibration technicians, and provide space and resources for calibration activities.

Choosing the Right Instrument Calibration Service

To ensure you have the most beneficial outcome when choosing an instrument calibration service, it is important to compare several companies using our directory of instrument calibration services. Each instrument calibration service has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with them for more information or to request a quote. Review each instrument calibration service website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple instrument calibration service companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services